The argus feather spring for model 332 might sound like a complex technical component, but it’s quite fascinating once you understand its role.

Imagine your Model 332 as a well-orchestrated symphony – every part must work perfectly to create the desired result.

The Argus feather spring is like the conductor of this symphony, ensuring that everything moves and functions exactly as it should.

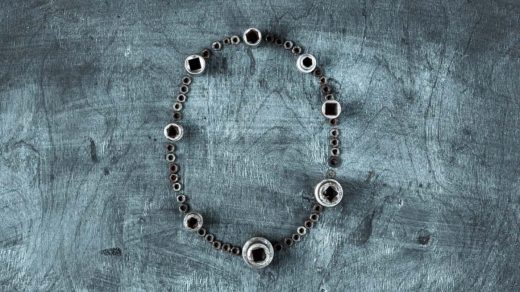

Unlike traditional coil springs found in everyday items, the Argus feather spring is a specialized component designed with precision and purpose.

It’s a flat, elongated piece of metal carefully wound into a spiral shape, creating a unique mechanism that provides just the right amount of tension and resistance where it’s needed most in your Model 332.

Argus Feather Spring for Model 332

What makes this spring particularly interesting is its ability to maintain consistent performance over time.

Whether you’re a technician working with these devices regularly or a device owner trying to understand your equipment better, knowing about this crucial component can help you maintain and optimize your Model 332’s performance.

Choosing the Right Argus Feather Spring

Selecting the appropriate feather spring isn’t just about finding a part that looks similar – it’s about ensuring perfect compatibility with your Model 332.

Think of it like finding the right key for a lock – it needs to match exactly to work properly.

Factors to Consider

When it comes to choosing your Argus feather spring, several critical factors come into play. Let’s break these down into manageable pieces:

Physical Specifications Table:

| Dimension | Description | Why It’s Important |

| Length | Total extended length | Determines fit and tension range |

| Width | Thickness of the metal strip | Affects spring strength and durability |

| Coil Diameter | Size of the spiral when wound | Must match housing specifications |

| Material Grade | Type of metal used | Impacts longevity and performance |

Material Considerations:

The material of your spring plays a crucial role in its performance. Most Argus feather springs are made from either:

- Stainless Steel

- Advantages:

- Excellent corrosion resistance

- High durability

- Consistent performance

- Best for: High-use environments

- Advantages:

- High-Carbon Steel

- Advantages:

- Superior tensile strength

- Good fatigue resistance

- Cost-effective

- Best for: Standard applications

- Advantages:

The choice of material should be based on your specific usage conditions and requirements. Environmental factors like humidity and temperature can influence which material would work best for your situation.

Identifying the Correct Spring

Finding the exact spring you need involves a systematic approach. Here’s how you can ensure you get the right match:

Documentation Method:

Start by gathering all available information about your Model 332. This includes:

- Original manufacturer documentation

- Service history records

- Previous replacement records

- Model-specific specifications

Measurement Process:

If you’re working with an existing spring, take precise measurements using:

- Digital calipers for width and thickness

- Flexible measuring tape for total length

- Radius gauge for coil measurements

Expert Consultation:

Sometimes, getting professional input can save time and prevent costly mistakes. Consider:

- Contacting the manufacturer directly

- Consulting with certified technicians

- Checking with authorized dealers

- Joining professional forums or communities

Installing the Argus Feather Spring

Installation is a critical process that requires attention to detail and patience. Let’s break this down into manageable steps while understanding the importance of each stage.

Pre-Installation Preparation

Before you begin the actual installation, proper preparation is essential. Here’s what you need to do:

Tool Checklist:

| Tool | Purpose | Essential/Optional |

| Precision Screwdrivers | Component removal | Essential |

| Needle-nose Pliers | Spring manipulation | Essential |

| Work Light | Visibility | Essential |

| Magnifying Glass | Detail inspection | Optional |

| Anti-static Mat | Component protection | Recommended |

| Clean Cloth | Surface cleaning | Essential |

Workspace Setup:

Create an optimal environment for installation by:

- Choosing a well-lit area

- Setting up a clean, flat workspace

- Organizing tools within easy reach

- Having a container for small parts

- Ensuring proper ventilation

Step-by-Step Installation Process

The installation process requires methodical attention to detail.

Here’s a comprehensive breakdown:

- Device Preparation Start with the basics:

- Power down the device completely

- Disconnect from any power sources

- Allow the device to cool if it’s been operating

- Document the current configuration (photos help)

- Access and Removal Carefully gain access to the spring:

- Remove access panels in the correct order

- Document each step of disassembly

- Keep screws and components organized

- Note the orientation of the old spring

- Spring Installation Now for the crucial part:

- Clean the spring housing thoroughly

- Inspect for any damage or wear

- Orient the new spring correctly

- Install the following manufacturer specifications

- Verify proper seating and tension

- Testing and Verification Before completing reassembly:

- Check spring movement

- Verify tension is correct

- Ensure no binding or catching

- Test related components

Safety Precautions

Safety should never be compromised during installation. Here are essential safety measures:

Personal Safety:

- Wear appropriate eye protection

- Use protective gloves when needed

- Maintain good posture while working

- Take regular breaks to prevent fatigue

Device Safety:

- Use anti-static protection

- Avoid excessive force

- Keep track of all components

- Work in a clean environment

Common Installation Mistakes

Learning from common errors can help you avoid problems:

Installation Pitfalls Table:

| Mistake | Consequence | Prevention |

| Incorrect Orientation | Malfunction | Double-check alignment |

| Over-tensioning | Premature wear | Follow specs exactly |

| Rushed Installation | Poor performance | Take your time |

| Skipped Testing | Unknown issues | Test thoroughly |

Maintenance and Care

Proper maintenance ensures optimal performance and longevity of your Argus feather spring.

Regular Maintenance Schedule

Establish a routine maintenance schedule:

Maintenance Timeline:

- Daily Operations:

- Monitor for unusual sounds

- Observe performance changes

- Note any irregularities

- Weekly Checks:

- Visual inspection

- Basic function testing

- Clean accessible areas

- Monthly Tasks:

- Detailed inspection

- Thorough cleaning

- Performance testing

- Documentation review

Signs of Wear and Tear

Knowing when to replace your spring is crucial. Watch for these indicators:

Physical Signs:

- Visible corrosion or rust

- Deformation of spring shape

- Unusual wear patterns

- Changes in surface texture

Performance Indicators:

- Inconsistent tension

- Unusual noises during the operation

- Reduced efficiency

- Irregular movement

Frequently Asked Questions

- Q: What makes the Argus feather spring different from regular springs?

A: The Argus feather spring is a specialized flat spring designed specifically for the Model 332. Its unique spiral design and precise specifications make it different from standard coil springs, allowing for more controlled and consistent tension.

- Q: How often should I inspect my Argus feather spring?

A: Perform visual inspections monthly and conduct thorough performance checks quarterly. However, if you notice any changes in device performance, inspect immediately.

- Q: Can I install the spring myself, or do I need a professional?

A: While installation is possible as a DIY project, it requires careful attention to detail and proper tools. If you’re not confident in your technical abilities, consulting a professional is recommended.

- Q: How long does an Argus feather spring typically last?

A: With proper maintenance and normal use, an Argus feather spring can last several years. However, lifespan varies based on usage patterns, environmental conditions, and maintenance quality.

Also Check:

- Lab-banana.com Business

- 5StarsStocks.com Nickel

- Ellen Yarnell Hollidaysburg PA Obituary

- Procurementnation.com Shipping

Conclusion:

Understanding and maintaining the argus feather spring for model 332 is crucial for optimal device performance.

This guide has covered the essential aspects of selection, installation, and maintenance.

Remember these key points:

- Choose the right spring based on the exact specifications

- Follow proper installation procedures

- Maintain regular maintenance schedules

- Monitor for signs of wear

- Address issues promptly

With proper care and attention, your Argus feather spring will provide reliable service and maintain the quality performance of your Model 332.